SAFILO 128 CA3

wire diameters

0.60 – 0.80

1.00 – 1.20 – 1.60

MM diameter

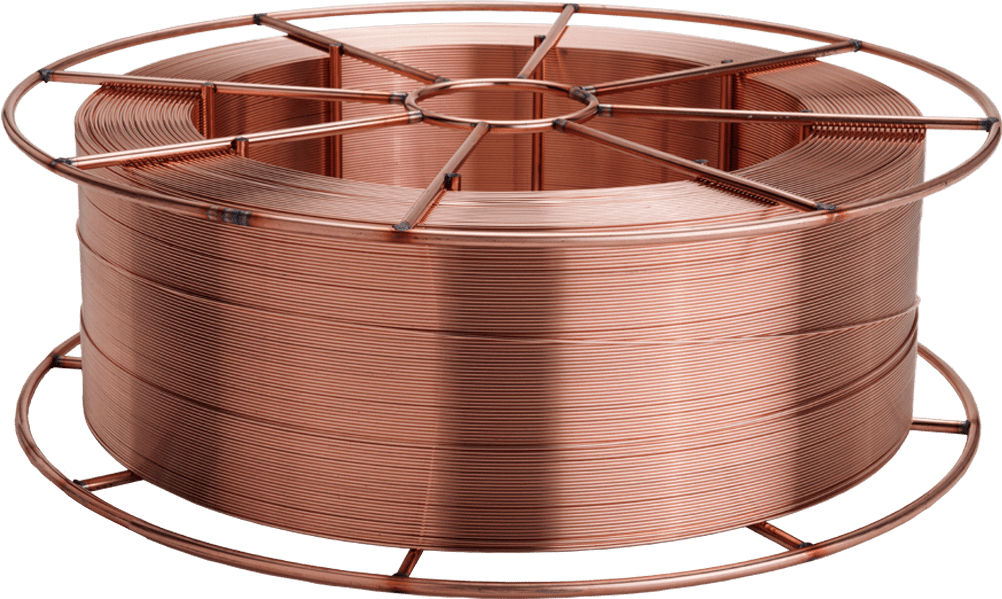

wire coils

5 and 15

KG weight

wire drums

280

KG weight

Solid wire for MIG/MAG welding for carbon steels to be used in processes under CO2 gaseous protection, EN ISO 14175 C1, or Ar/CO2 and Ar/CO2/O2 mixtures, EN ISO 14175 M21-M33.

standard

EN ISO 14341-A:11

AWS A5.18:05

classification

G 46 5 M21 4Si1 / G 46 4 C1 4Si1

ER70S-6

operational data

Positions: PA, PB, PC, PD, PE, PF, PG

Polarity and current: D.C. +

average wire chemical composition

C %

0.065 - 0.085

Mn %

1.60 - 1.70

Si %

0.90 - 1.00

S %

max

0.002

P %

max

0.002

Cu % *

max

0.30

Cr %

max

0.15

Ni %

max

0.10

mo %

max

0.10

* casting value to which the Cu wire coating must be added (between 0.05 and 0.15% on average)

average mechanical features of the deposit

Average values

*

EN ISO

Minimum values

AWS

Minimum values

Tensile strength

Rm

600 MPa

530 MPa

480 MPa

Enervation

Rs 0,2 %

500 MPa

460 MPa

400 MPa

Resilience

A % (L=5d)

26

20 (L=5d)

22 (L=5d)

Resilienza

ISO –V KV

80 (J) a – 20°C

50 (J) a – 50°C

47 (J) a – 40°C

C1/M21

AWS27 (J) a – 29°C

*The indicated values refer to welds carried out under the following conditions: Base Metal: S 355J2 N EN 10025-2. Protective Gas: EN ISO 14175 M21. Samples: TENSILE TEST conforming to EN ISO 5178 / EN ISO 6892-1 d . 10mm section 78.5 mm² – lengthwise at half thickness. Samples: RESILIENCE TEST compliant with EN ISO 9016 / EN ISO 148-1 80 mm² sect. – samples taken at half thickness of the weld bead. Heat Treatments: TESTS CARRIED OUT IN “AS WELDED” CONDITION.

field of use

Steels with yield strength up to 460 MPa

Structural steels for construction

EN 10025-2 S185, S235, S275, S355, E295, E335, E360

Steels for pressure vessels

EN 10028-2 P235GH, P265GH, P295GH, P355GH

EN 10028-3 P255NH, P275N, P275NH, P355 N, P355NH

Fine grain structural steels

EN 10025-3 S275N, S355N, S420N, S275NL, S355NL, S420NL,S460Nl

EN 10025-4 S275M, S275ML, S355M, S355ML, S420, S420ML,S460NL

Steel for pipes

EN 10208-1 L210, L240, L290, L360

EN 10208-2 S275M – S275ML – S355M – S355ML – S420M – S420ML

EN 10216-1 P235T1, P235T2, P275T1

available in

coils

5 and 15

KG

KG