SAFILO 128 CA1

wire diameters

0.60 – 0.80

1.00 – 1.20 – 1.60

MM diameter

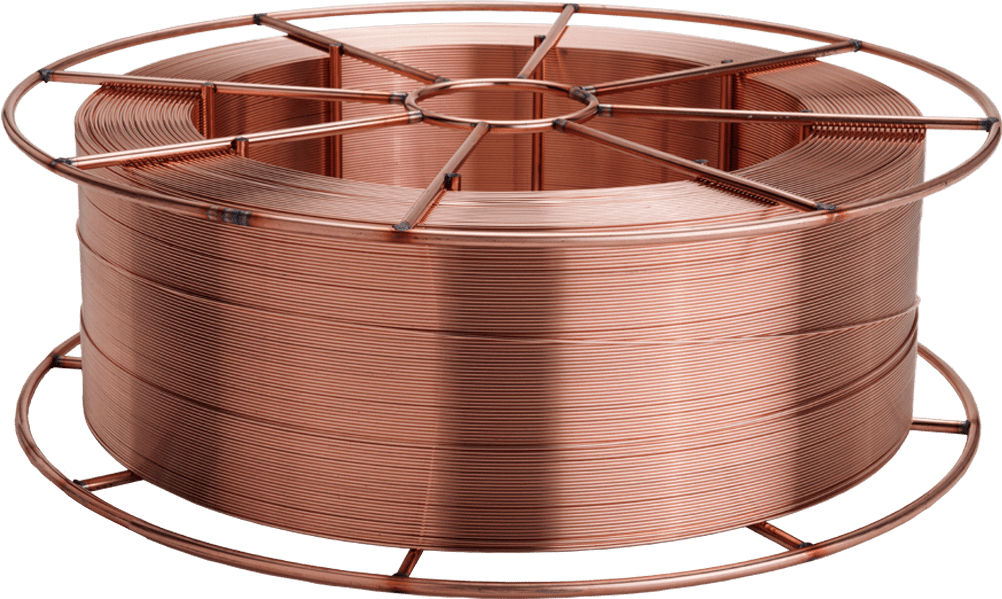

wire coils

5 and 15

KG weight

wire drums

280

KG weight

Solid wire for MIG/MAG welding for carbon steels to be used in processes under CO2 gaseous protection, EN ISO 14175 C1, or Ar/CO2 and Ar/CO2/O2 mixtures, EN ISO 14175 M21-M33.

standard

EN ISO 14341-A:11

AWS A5.18:05

classification

G 42 4 M G2Si1

ER70S-3

operational data

Positions: PA, PB, PC, PD, PE, PF, PG

Polarity and current: D.C. +

average wire chemical composition

C %

0.060 - 0.080

Mn %

1.00 - 1.30

Si %

0.50 - 0.70

S %

max

0.020

P %

max

0.020

Cu % *

max

0.30

Cr %

max

0.15

Ni %

max

0.15

Mo %

max

0.10

* casting value to which the Cu wire coating must be added (between 0.05 and 0.15% on average)

average mechanical features of the deposit

Average values

*

EN ISO

Minimum values

AWS

Minimum values

Tensile strength

Rm

540 MPa

500 MPa

480 MPa

Enervation

Rs 0,2 %

440 MPa

420 MPa

400 MPa

Stretching

A % (L=5d)

30

20 (L=5d)

22 (L=5d)

Resilience

ISO –V KV

80 (J) a – 20°C

60 (J) a – 40°C

47 (J) a – 40°C

C1/M21

27 (J) a – 29°C

*The indicated values refer to welds carried out under the following conditions: Base Metal: S 355J2 N EN 10025-2. Protective Gas: EN ISO 14175 M21. Samples: TENSILE TEST conforming to EN ISO 5178 / EN ISO 6892-1 d . 10mm section 78.5 mm² – lengthwise at half thickness. Samples: RESILIENCE TEST compliant with EN ISO 9016 / EN ISO 148-1 80 mm² sect. – samples taken at half thickness of the weld bead. Heat Treatments: TESTS CARRIED OUT IN “AS WELDED” CONDITION.

field of use

Steels with yield strength up to 420 MPa

Structural steels for construction

EN 1002S2 S185, S235, S275, S355, E295, E335, E360

Steels for pressure vessels

EN 10028-2 F235GH, F265GH, P295GH, P355GH

EN 10028-3 P255NH, P275N,P275NH, P355N, P355NH

Fine grain structural steels

EN 1002S-3 S275N, S355N,S420N, S275NL, S355NL, S420NL

EN 10025-4 S275M, S275ML, S355M, S355ML, S420, S420ML

Steel for pipes

EN 10208-1 L210, L240, L290, L360

EN 10208-2 S275M – S275ML – S355M – S355ML – S420M – S420ML

EN 10216-1 P235T1, P235T2, P275T1

available in

coils

5 and 15

KG

KG